Laser marking is a way of marking or labeling of workpieces and materials with a laser equipment. CO2 laser marker, fiber laser marker and UV laser marker are the well-known laser machines. Depending on the material type and the quality requirement, as well as wave length differences and properties of different lasers, different laser markers has different applications.

Benefits of laser marking

High-precision and constant marking

With high precision, even very delicate graphics, 1-point fonts and very small geometries will turn out clearly legible. At the same time, marking with the laser ensures constant high-quality results.

Laser marked dataplate (aluminum)

High marking speed

Laser marking is one of the fastest marking processes available in the market. This results in high productivity and cost benefits during manufacture. Depending on the material structure and size, different laser sources (e. g. fiber lasers) or laser machines (e. g. galvo lasers) can be used to further increase the speed.

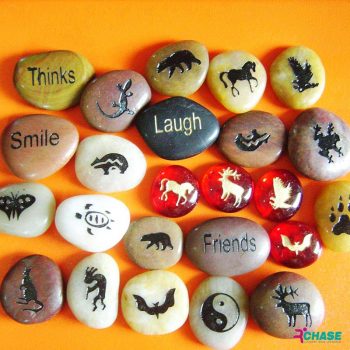

Durable marking

Laser etching is permanent and at the same time resistant to abrasion, heat and acids. Depending on the laser parameter settings, certain materials can also be marked without damaging the surface.

What materials can be marked with a laser?

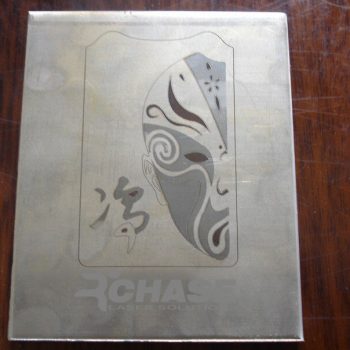

Metals like Stainless steel, aluminum, gold, silver, titanium, bronze, platinum or copper, Nonmetal materials such as acrylic, double color board, Plexiglas, glass, bamboo, wood, rubber, marble, granite, ceramic, porcelain, tiles, leather, cloth, plastic, stone, ABS, MDF, paper, hard paper, laminates, rubber, crystal, electronic components, etc.