Description

Assume full responsibility to meet all demands of our clients; achieve continuous advancements by promoting the growth of our clients; become the final permanent cooperative partner of clients and maximize the interests of clients for fiber welding machine,handheld laser welding machine,laser welder, Our company will continue to adhere to the, superior quality, reputable, the user first, principle wholeheartedly. We warmly welcome friends from all walks of life to visit and give guidance, work together and create a brilliant future!

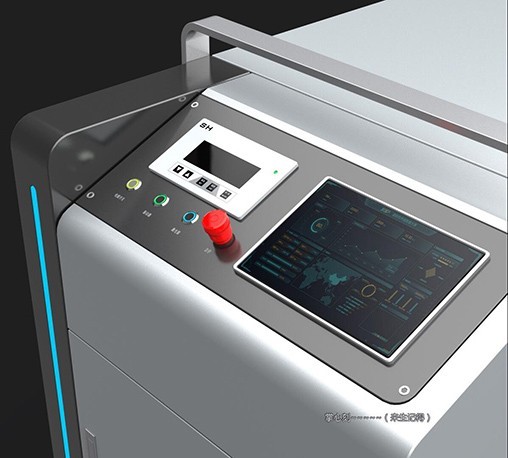

Fiber laser welder

Features and Benifits

1. Accurately and high precision welding machine, can weld small and complex font and LOGO.

2. Fast speed, high effficiency.

3. No color difference after welding, no trace, beautiful appearance, No raised welding spot on welding surface. Do not need polishing grinding process, save work time.Low noise, non-pollution.

4. Long lifespan, up to 100000 hours.

Technical parameters:

|

1

|

Device name

|

Handheld fiber laser welding machine

|

|

2

|

Laser power

|

500W, 800W, 1000W, 1500W

|

|

3

|

Laser wavelength

|

1080NW

|

|

4

|

Fiber length

|

Standard 10M up to 15M

|

|

5

|

Way of working

|

Continuous / Modulation

|

|

6

|

Welder speed range

|

0 ~ 120 mm) / s

|

|

7

|

Cooling water machine

|

Industrial thermostatic water tank

|

|

8

|

Working environment temperature range

|

15 ~ 35 “C

|

|

9

|

Working environment humidity range

|

<70% non-condensing

|

|

10

|

Recommended welding thickness

|

0.5-3mm

|

|

11

|

Welding gap requirements

|

≤0. 5mm

|

|

12

|

Operating Voltage

|

AV380V

|

Advantages in comparison with other welding equipment:

|

Compare items

|

Traditional welding

|

Laser welding

|

Chu Shuo New Generation Laser Welding

|

|

Heat input to the workpiece

|

very high

|

low

|

low

|

|

Deformation of workpiece, undercut

|

Big

|

small

|

small

|

|

Bonding strength with base metal

|

general

|

it is good

|

very good

|

|

Follow-up

|

Sanding

|

No sanding or little sanding required

|

No sanding or little sanding required

|

|

Welding speed

|

general

|

2 times more than argon arc welding

|

2 times more than argon arc welding

|

|

Applicable materials

|

Stainless steel. Carbon steel. Galvanized sheet

|

Stainless steel. Carbon steel. Galvanized sheet

|

Stainless steel. Carbon steel. Galvanized sheet

|

|

Consumables

|

Consumables

|

Less consumables

|

Less consumables

|

|

Difficulty of operation

|

complex

|

general

|

simple

|

|

Operator safety

|

Unsafe

|

Safety

|

Safety

|

|

Environmental impact

|

Not environmentally friendly

|

Environmental protection

|

Environmental protection

|

|

Welding fault tolerance

|

it is good

|

not good

|

it is good

|

|

Swing welding

|

no

|

no

|

Have

|

|

Spot width adjustable

|

no

|

no

|

Have

|

|

Comparison of welding quality

|

difference

|

general

|

well

|

Welding penetration data (wobble welding head)

|

Power / Depth

|

stainless steel

|

Carbon steel

|

Galvanized sheet

|

|

500W

|

800W

|

1000W

|

1500W

|

|

0.5-0.8mm

|

0.5-1.2mm

|

0.5-1.5mm

|

0.5- -3mm

|

|

0.5-0.8mm

|

0.5-1.2mm

|

0.5-1.5mm

|

0.5- -3mm

|

|

0.5-0.8mm

|

0.5-1.0mm

|

0.5-1.2mm

|

0.5- -2.5mm

|

Laser Welding Machine Applied Industries:

1. Auto parts industry, Engine cylinder gasket, Hydraulic tappet seal welding.

2. Filter seal welding, The sport plug welding, The valve push rod welding.

3. Anti-collision airbag electric detonator seal welding, The crankshaft or cylinder liner or heat treatment, etc.

4. Stainless steel advertising words, Microelectronics components, precision parts. High digital components, optical fiber connector, medical apparatus and instruments, etc.

Laser Welding Machine Applied Materials:

Titanium, aluminum, copper, zinc, gold, sliver and many other metal and alloy, carbon steel and stainless steel materials, and also cooper-brass, cooper-titanium, nickel-cooper, cooper-titanium and many other heterogeneous metals.

Laser Power Options: 300w-6000w

Reviews

There are no reviews yet.